Thermal analysis and flow analysis

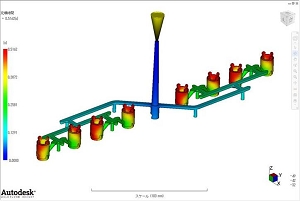

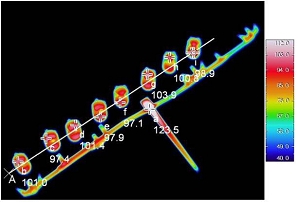

Unique thermal analysis is implemented by monitoring the actual temperature of molding products at trial manufacture and test molding, using high-precision thermographic cameras. Combining the result of the thermal analysis and simulation result in flow analysis will lead to mold building that enables stable mass production.  Result of flow analysis

Result of flow analysis  Result of thermal analysis

Result of thermal analysis

Three-dimensional CAD design

Since installing Unigraphics Ver. 18.0 in September 2002, we have been using three-dimensional CAD for designing molds.

At present, dedicated designers use NX5 at Toyoshiro factory, and make molds with the "stabilization technology for mass production of quality products" in order to meet high demands customers and achieve high molding efficiency at our company.

Also, CAM uses FF-AUTO.

Every day, considering how to mold quality products for a long period of time during mass production, we improve efficiency of gas vents for various resin materials and select effectively mold materials and surface coating for abrasion and erosion of resin materials.

Please try out our know-how and cost efficiency, which we have acquired in the automobile industry, for manufacturing molds and mold parts.

Mold design

Mold design

Mold building

OHARA Jushi Kogyo co., ltd.